The heating-for-buildings kit includes additional innovations to the essential kit that are specific to the smart electrification of heating in the residential sector (Table 5.4). Hybrid heat pumps offer an intermediate step between fossil fuel–based heating and 100% electric heating, for example, while thermal storage and the matching of solar resources with demand offer major gains in flexibility and overall system efficiency.

The heating-for-industry kit includes the innovations needed to electrify heating in the industry sector. Industries are profit driven and typically operate continuously at high-capacity factors. Innovations may thus encounter resistance if they significantly affect operations. On the other hand, innovations such as high-temperature heat pumps (see Box 5.1) and waste heat recovery (Table 5.5) have the potential to significantly increase the efficiency of operations while also reducing emissions from fossil fuel use.

BOX 5.1 Industrial high-temperature requirements

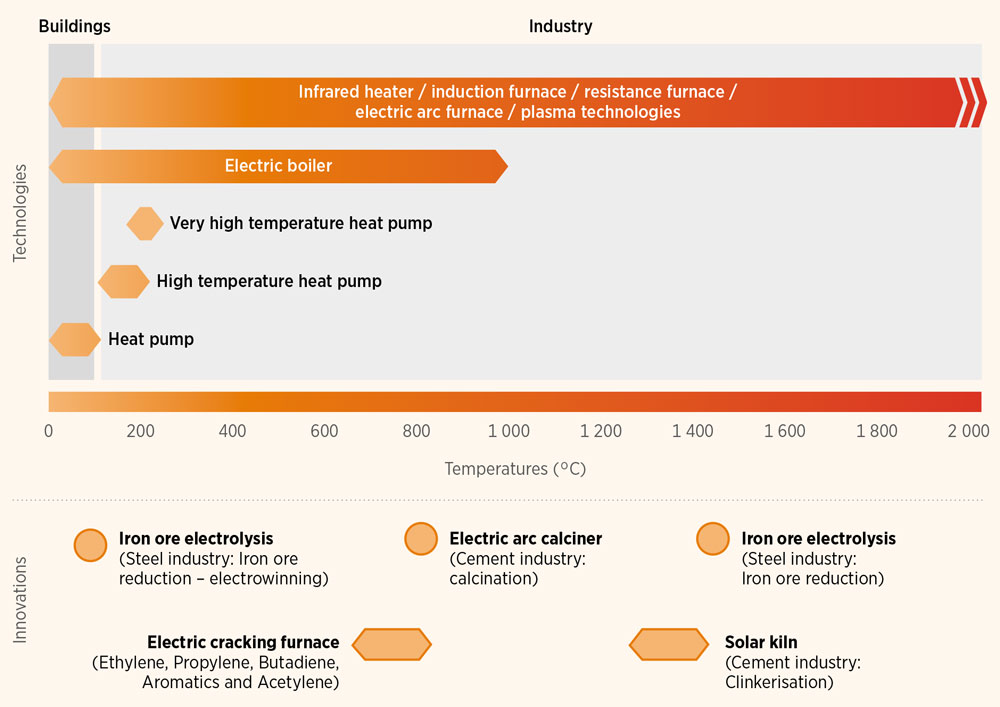

Industrial processes require a wide range of temperatures. No singular technology can thus meet all industrial energy needs. Figure 5.2 shows how different technologies can provide the required temperatures, which can go above 1 000°C in specific sectors.

FIGURE 5.2 Temperature ranges and technologies for industry sectors

For some uses, electricity can be used directly in electric furnaces, electric boilers, heat pumps or other electrolytic processes. One innovation still under development is the high-temperature heat pump, which can deliver heat at up to 150°C (Arpagaus et al., 2018). When commercially available, these pumps could be used for applications such as injection moulding in the plastic industry or many drying processes, adding significant energy savings, as shown successfully in the EU DryFiciency project (DryFiciency, 2016).

Three main industrial sectors – chemical, cement and steel – are the most challenging to electrify, but promising solutions are being developed. For the chemical industry, electric crackers (e-crackers) are in the pilot phase. The cement industry is working on new kilns where heat is provided via plasma generators (Somers, 2020). The steel sector is piloting new electrolytic reduction processes. In addition, these industries might be electrified indirectly through renewable fuels like green hydrogen.

The district heating kit aims to shape the smart electrification strategy for thermal grids and includes the fourth and fifth generations6 of thermal grids and waste heat-to-power technologies (4GDH and 5GDG). Waste heat-to-power technologies are not included in the buildings kit because they require significant volumes to become profitable. However, the market innovations and business models are the same or similar across building and district heating (Table 5.6).