Electrolysers as grid service providers

Overview of the status and impact of the innovation

What

Electrolysers can ramp production up and down quickly, offering a flexible load that provides valuable grid-balancing and stability services. Three electrolyser technologies – PEM, ALK and AEM – can participate in existing primary, secondary and tertiary grid-balancing markets.

Taking advantage of this flexibility, however, may require new market designs that open up the system services market to new actors, such as electrolysers, or that reward hydrogen producers for specific services, such as providing fast reserves or managing overgeneration from renewable sources (IRENA, 2021b).

Why

Enabling electrolysers to provide grid-balancing services will not only make the energy system more adaptable, but also enable hydrogen producers to gain additional revenues, potentially reducing the final price of green hydrogen.

BOX 9.7 Electrolysers’ capability to provide ancillary services

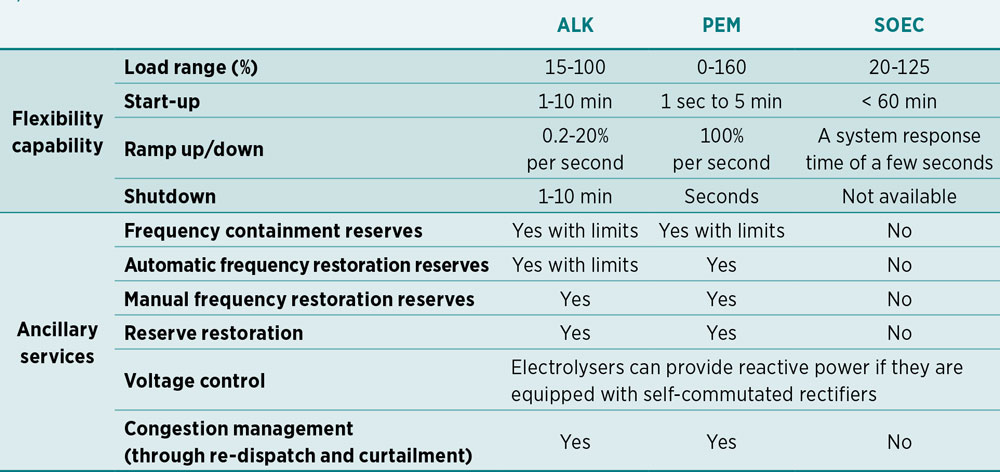

Commercially viable electrolyser technologies could, in principle, provide a wide range of frequency and non-frequency ancillary services as well as congestion management. It is worth noting that the role for power-to-hydrogen projects in providing flexibility will ultimately depend on their competitiveness compared to other storage technologies. If these alternatives (e. g. batteries) can provide flexibility at lower cost, the need for power-to-hydrogen capacity may be significantly reduced.

Table 9.4 summarises the flexibility capability of alkaline (ALK), polymer electrolyte membrane (PEM) and solid oxide electrolyser cell (SOEC) electrolysers and which ancillary services they are able to currently provide.

TABLE 9.4 Flexibility capacity and services of three types of electrolyser

BOX 9.8 An electrolyser providing ancillary services in Germany

In Germany, the participation of small electrolysers in the market is made possible by aggregating them into virtual power plants (IRENA, 2021b). Tests with an alkaline electrolyser owned by thyssenkrupp in Duisburg show that it can ramp production up and down fast enough to enter the market for primary reserve, where the entire service offering has to be fully delivered within a maximum of 30 seconds and be continuously available for at least 15 minutes (thyssenkrupp, 2020).

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models