Hydrogen industrial hub

Overview of the status and impact of the innovation

What

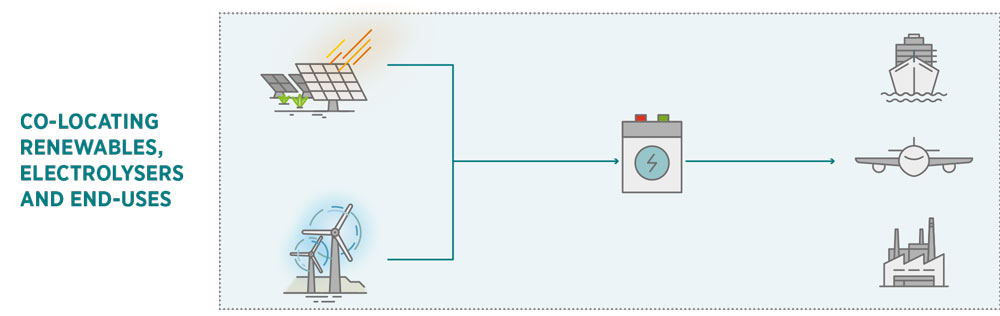

Hydrogen industrial hubs group together renewable electricity generators, electrolysers for green hydrogen production and hydrogen storage facilities with industrial consumers (Figure 9.11). The idea is to locate all these facilities in close proximity to minimise the hydrogen delivery infrastructure, reduce logistics costs and enable the use of massive clean hydrogen production plants. These hubs thus provide economies of scale in producing, delivering and using hydrogen.

FIGURE 9.11 Co-locating renewables and electrolysers with end uses

Why

Hydrogen hubs reduce the costs of transporting hydrogen and electricity from producers to consumers, while also ensuring reliable hydrogen supply for users and providing important economies of scale. All these benefits strengthen the business case for clean hydrogen investments.

BOX 9.22 Decarbonisation of a major industrial cluster in Valencia, Spain

The industrial district of Castellón is one of the largest ceramic industrial clusters in Europe, and accounts for 95% of the ceramic industry in Spain. Because the ceramic industry is so energy intensive, this single industrial cluster emits 33% of the total CO2 emissions in the Valencia region. The ORANGE.BAT project is designed to reduce those CO2 emissions by replacing natural gas with green hydrogen. It will use a 100 MW pressurised alkaline electrolyser system. The project will also make use of the electrolyser’s by-products. The oxygen will be used to improve the kiln process and the heat will be used for industrial and residential heating.

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models