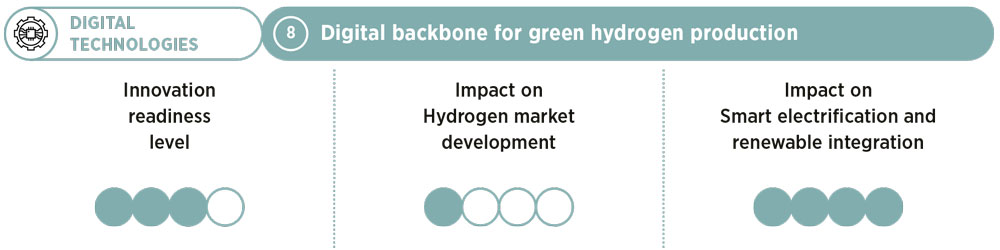

Digital backbone for green hydrogen production

Overview of the status and impact of the innovation

What

The Internet of Things (IoT) refers to physical devices that use electronics, sensors and software to collect and exchange large volumes of data over the Internet or across communication networks. This makes it possible to monitor, control and optimise the operation of electrolysers and other key elements of the hydrogen ecosystem. The use of big data and artificial intelligence (AI), for example, can improve supply and demand planning, and provide more accurate forecasts of variable renewable power generation or energy demand.

Roughly, electricity accounts for 70% of total hydrogen production costs (H2GreenSteel, 2022). This means that a data-driven operation is key. Forecasting tools for renewable resource availability, production planning or software for the optimisation of storage capacity and electrolyser operation can support the deployment of the green hydrogen economy.

Why

Building and operating the future hydrogen economy will require substantial data analysis. From the very beginning, for instance, it is vital to use data on the renewable energy potential in various regions, the potential constraints for hydrogen transport, the expected levels and locations of hydrogen demand, and local and international hydrogen prices (including country-specific taxes) to determine the best locations for hydrogen production plants or the most effective transport network designs.

Then, as the hydrogen economy expands, these digital technologies offer major benefits. They enable greater integration of variable renewable generation into the power system and more efficient coupling of electrolysers with generation sources. They facilitate increased automation and improve the forecasting of everything from renewable energy production to hydrogen demand, making it possible to improve the overall efficiency of the green economy.

BOX 9.3 HyAI (Hydrogen Artificial Intelligence) project

The HyAI project entailed the development of AI’s use for hydrogen production and storage. It was a partnership among H2GO Power, the European Marine Energy Centre (EMEC) and Imperial College London, and was funded by Innovate UK and the Sustainable Innovation Fund. The project began in October 2020 and was completed in July 2021. The pilot project integrated weather data, electricity prices and energy data from EMEC’s hydrogen production plant in Orkney, Scotland, and then used AI algorithms to predict future power costs and user demand; the aim was optimising hydrogen production and storage. The first results showed that HyAI could improve the cost-effectiveness of hydrogen production and reduce power grid stress, allowing increased shares of renewable energy. A follow-on HyAI 2.0 project, begun in March 2022, is deploying the AI platform at the EMEC facility to control hydrogen production in real time.

BOX 9.4 H₂ Green Steel optimisation software

The Swedish firm H₂ Green Steel champions a digital hydrogen economy based on the data-driven optimisation of processes across the entire hydrogen value chain. This digitalisation can enable the cost-effective production of a wide range of products including green steel, ammonia and methanol. The company is developing two optimisation software tools in hopes of achieving the lowest-cost hydrogen production possible, regardless of the location of operations. It has also developed software to plan the optimal configuration of hydrogen plants in a modular way, making the design process more time and cost efficient, and informed by real-world experiences.

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models